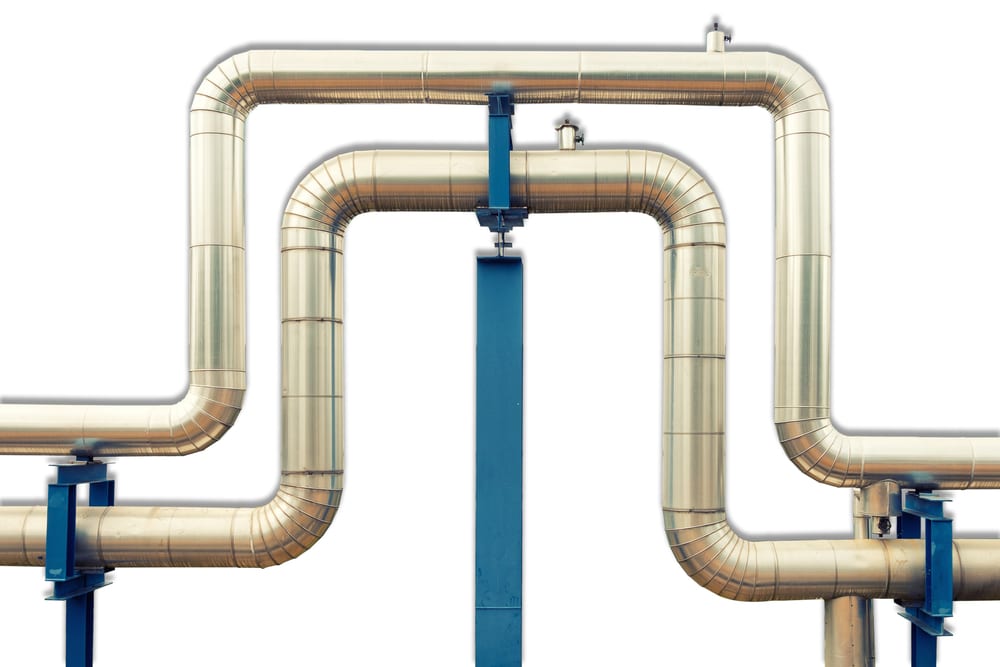

Steam Pipework Installation

At Valveforce, we are experts in the field of steam solutions engineering and condensate piping systems. We can offer real value to our customers. Valveforce has vast experience in steam engineering, supplying and installing steam distribution, steam pipework installation and condensate recovery systems. But, we also support our customers where steam is a serious utility on site.

Speak with our experts

Fill out our quick and easy contact form with your enquiry and we'll get back to you.

Steam Piping System Services

Our steam piping systems designs help with energy saving, efficiency improvements, plant upgrades and expansion. We are experienced with working in energy centres. As a result, we can support you if there is a requirement for a new boiler feed tank, boiler blowdown vessel, boiler upgrades, and larger let down stations.

It is key to look at how a steam system is utilised and controlled. However, part of this process involves manufacturing heat exchanger packages and condensate return sets. Valveforce, and it's sister company Heatxforce, can offer you the right heatexchanger packages to suit your requirements.

In addition to our expertise in steam solutions engineering, Valveforce also offers comprehensive maintenance and repair services for steam systems. Our team of highly skilled technicians is available to provide regular inspections, troubleshooting, and repairs to ensure the optimal performance and longevity of your steam piping systems.

At Valveforce, we pride ourselves on our ability to deliver tailored solutions that meet the unique needs of each customer. Whether you require a complete steam system installation, upgrades to your existing system, or ongoing support and maintenance, our dedicated team is ready to assist you. Contact us today to discuss your steam engineering needs and discover how Valveforce can add value to your operations.

Steam Pipework Installation Explained

Design

Proper design is crucial to ensure the safe and efficient operation of the steam piping system. It includes determining the pipe size, material, and layout, as well as considering factors like pressure and temperature ratings, insulation requirements, expansion and contraction, and safety precautions.

Material Selection

Steam pipes are typically made of carbon steel due to its strength and heat resistance. The material must be selected based on the operating pressure and temperature of the steam.

Pipe Sizing

The diameter of the steam pipes should be determined based on the steam flow rate and pressure drop requirements. Pipe sizing calculations are performed to ensure the proper flow of steam to the intended destinations.

Installation

The installation process starts with preparing the site and making necessary markings for the pipe layout. The pipes are then cut to the required length and threaded or welded together using appropriate fittings and joints. Valves, flanges, and other necessary components are also installed at appropriate points in the system.

Insulation

Steam piping systems are typically insulated to minimize heat loss and improve energy efficiency. Insulation material, such as mineral wool or fiberglass, is applied around the pipes and secured with metal cladding or jackets.

Testing and Commissioning:

Once the piping system is installed, it needs to be tested for leaks and pressure integrity. Various tests, such as hydrostatic testing, are performed to ensure that the system can handle the specified operating conditions safely.

Valveforce Steam Piping Supplier

Valveforce as your steam piping system supplier can be a true asset to your business! Speak to us today about assessing your steam piping design.

To see a case study on Steam Injection Systems Click Here.

To see a case study on how Valveforce’s steam system design specialist expertise helped a Balloon Dipping Plant Click Here.