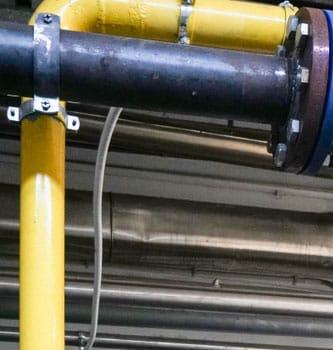

Pneumatic Control Valves

Valve Express service available

Valveforce has the capabilities to help process plants with their most demanding control problems. Whether you need to find a cost effective pneumatic control valve for cooling water service, or a stainless steel globe valve for your aggressive or pure processes we will be able to get the correctly specified product for your needs.

Speak with our experts

Fill out our quick and easy contact form with your enquiry and we'll get back to you.

Control Valve Expertise

In the modern day manufacturing world in day-to-day plant operation, you have a long list of concerns, like meeting production schedules, maintaining product quality, and improving the efficiency of plant utilities, to name just a few. The last thing you should have to worry about is the performance of your plant's control valves. Valveforce are specialists in the design and supply of energy and severe service control valves for gas, steam and water applications. By working with Valveforce we give you the total project support and complete of mind that your control valves are working efficiency.

Pneumatic Control Valves Explained

The pneumatic control valve manipulates a flowing fluid, such as gas, steam, water, or chemical compounds to compensate for the load disturbance and keeps the regulated process variable as close as possible to the desired set point.

This type of Valve with its classic globe body shape, which reflects its name, uses the variable area generated between the plug and seat to control fluid flow. It is very versatile offering reduced trim options as well as a variety of special trims for severe high pressure drop applications. This style of valve is easily adapted for use on cryogenic temperatures and for high temperature duties.

This valve is preferred for:

- Tight shut – off

- Positioning accuracy

- High range-ability

- Simplified maintenance

Valveforce understand that the process requirements differ. Therefore this linear movement valve comes in both equal percentage and linear characteristics. When it comes to materials, we can offer options for carbon steel as well as stainless steel body. For the trim material there are option for standard Stainless steel, Stainless steel alloy such as Monel, half stellite or full stellited trim for severe service applications to avoid flashing or cavitation and also soft material such as PTFE for tight shut off. There are single stage trim option and also multi stage trim option for reducing noise.

Valveforce recognise that these advantages satisfy the majority of pneumatic control valve applications throughout the process and power industries in control of Air, Steam, Water, Gas, Chemicals.

Our specialist valve engineers work as alongside your team to assist in the design, specification and delivery of your valve and provide you with the application specific advice and up to date information.

Valveforce are an independent company therefore we can supply a whole range of pneumatic control valve from leading manufactures around the world. We offer highly competitive prices on a quality range to cover all pressure classes and temperature ratings. We offer these valves in both DIN and ANSI whichever type you need to make your plant running smoothly and efficiently.

If you are interesting in joining the many energy contractors already saving money, improving energy efficiency and ensuring compliance with our support please get in touch with our valve specialists on 0121 711 1908.

Valveforce Pneumatic Control Valves

Two way Pneumatic Control Valve

- Special pneumatic control valve designed to handle a wide range of fluids such as water, thermal oil, steam, nitrogen & natural gases

- Optimised modular construction for repair and application requirements

- Large range of pneumatic actuation forces available to meet most services

Mixing & Diverting Pneumatic Control Valve

- Control valves for use in hot water & thermal oil systems to maintain constant fluid temperature supply

- Excellent control guaranteed by finely engineered three port junction & plug

Pneumatic Control Valves For High Pressure Applications

- Resilient construction for severe service applications

- Maximum pressures of 80 bar with permissible pressure drops of up to 30 bar

- Applications include turbine bypass, let down & de-superheating stations

- Integral pilot control valve counteracts excessive back pressure

- Double & triple cage options allow for maximum protection against cavitation