Boiler Feed Water Tank

A boiler feed water tank plays an integral role within a steam system. Boiler feed water (a combination of return water and make-up water) is essential for steam boiler and steam generator operation. It must be carefully managed and controlled and of the highest quality available to ensure a long and efficient life for industrial boilers and steam lines.

Speak with our experts

Fill out our quick and easy contact form with your enquiry and we'll get back to you.

Boiler Feed Water Tank Explained

Feedwater must be treated to remove impurities and then correctly stored in a boiler feedwater tank before use.

A boiler feedwater tank (or hotwell tank) is an essential part of the steam system, yet often the last item to be considered during the plant room design process. However, the feed tank’s design can increase the reliability of the steam boiler/steam generator and steam system; and lead to substantial energy and water treatment savings being made.

The feed tank is where make-up water, steam boiler condensate return and blowdown flash steam come together and are stored; and the process of heating the feedwater begins. Essentially, properly maintained feed water from a well-designed boiler feedwater tank will help to:

- minimise the content of dissolved solids

- avoid damage to the steam boiler from thermal shock, oxygen pitting and corrosion

- maintain the desired steam output of the boiler

Capabilities

Capabilities

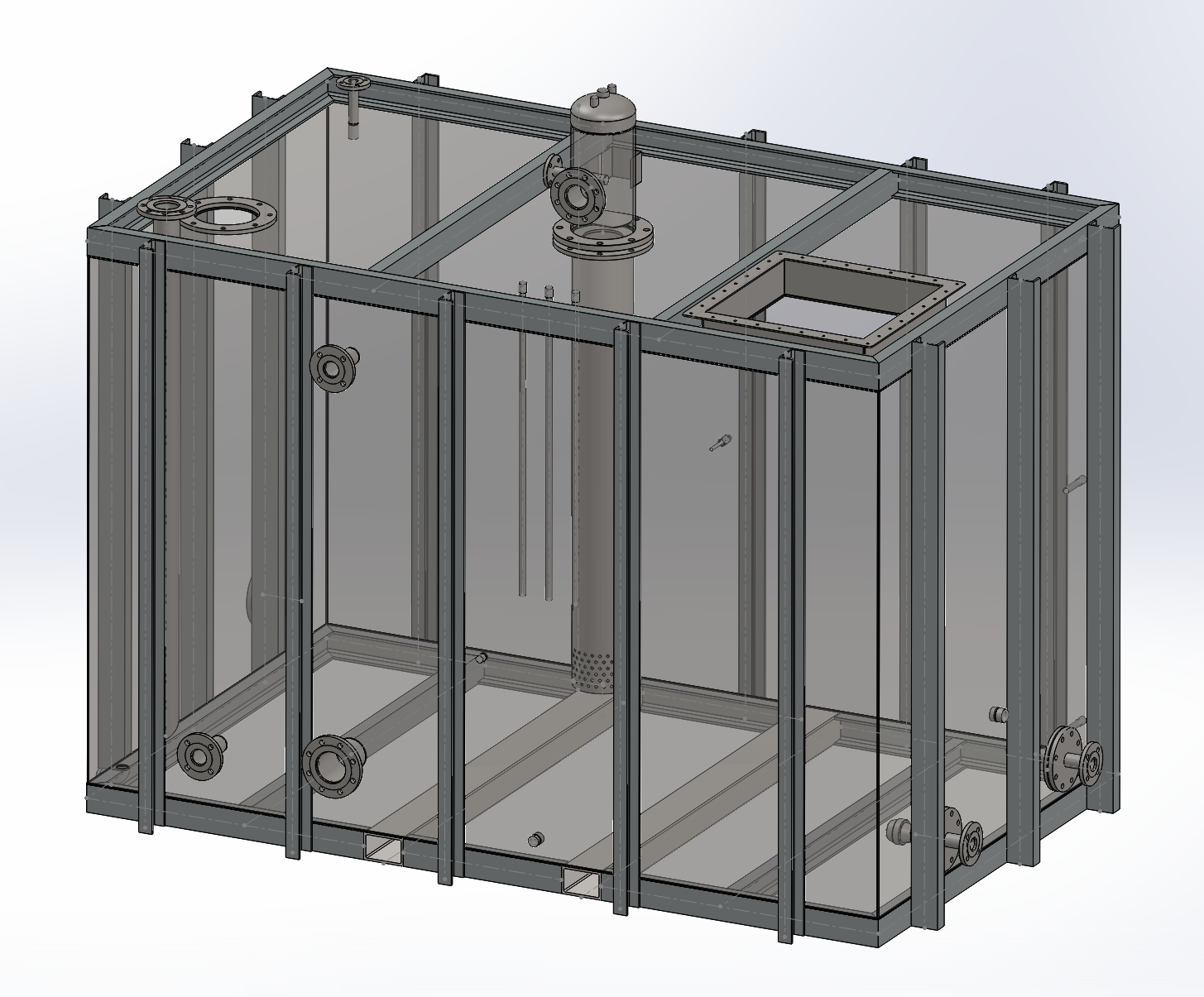

Designed as a complete sealed unit, a Valveforce boiler feed tank uses mechanical deaeration via a deaeration head or sparges to remove the majority of gases (including oxygen and carbon dioxide) from the make-up water and flash steam. The feedwater tank therefore forms an essential part of a steam system’s water treatment programme by:

- collecting condensate return

- introducing additional make-up water

- using blowdown flash steam heat recovery to preheat feedwater

- using steam injection for additional temperature control

- reducing excess oxygen from the boiler feedwater

- storing adequate volumes of feedwater

By incorporating a deaerator head, Valveforce feed tanks can significantly reduce the volume of steam that would, under standard working conditions, be vented from the tank to atmosphere. They therefore require less venting capacity than standard boiler feed tanks fitted with vented lids.

When properly designed and correctly installed into a steam system, a Valveforce boiler feedwater tank will also help to:

- Save energy by reducing waste flash steam

- Increase feedwater temperatures to reduce the quantity of chemicals required

- Eliminate corrosion of the steam boiler and condensate line

Capabilities

A well-designed boiler feed water tank will help the steam generating plant by:

- Helping to avoid damage to the boiler

A boiler undergoes thermal shock when cold water is introduced to the hot surfaces of the boiler wall and its tubes. Feed water of a higher temperature means a lower temperature difference and less risk of thermal shock. - Maintaining the designed output of the F&A rating (based on 100°C)

The lower the boiler feed water temperature, the more energy is used by the boiler to produce steam. It is important to maintain the feed water’s temperature as high as possible to maintain the required boiler output. - Eliminating cavitation of the boiler feed pump

Care must be taken when managing boiler feed water temperatures, as very high condensate return rates can result in excessive feed water temperature, which can cause boiler feed water pumps to cavitate. Care must be paid to the correct management of the boiler feed water temperature, with only the correct amount of steam injection being added.

Valveforce Boiler Feedtank Options

Available in standard capacities from 1,815 to 29,040 litres (400 to 6,400 gallons), Valveforce’s steam boiler feed tank benefits from all-welded construction using 5mm thick austenitic 304L stainless-steel plate, with all wetted parts (including connection sockets and flanges, internal pipework and sparges, manhole fittings and covers) we can also construct using austenitic stainless-steel.

Valveforce can provide a turnkey solution for its boiler feed water tanks, including:

- site surveys

- bespoke feed tank design and construction

- installation

- commissioning

- servicing/maintenance contracts

Temporary feedwater tanks are available when a site or project requires a bespoke feed water solution. During the design and build process of bespoke hotwell tanks, temporary Valveforce tanks ensure process continuation and uptime.

Valveforce can reverse engineer boiler feed tanks to be fabricated on a like-for-like basis. This ensures modifications and on-site works are minimised and the project delivered as effortlessly as possible.

If you’re looking for a new or replacement boiler feedwater tank, we can work together to manage your projects. Contact Valveforce now to discuss your requirements,