Design and Build Installation Provider

A Complete Design and Build Installation Provider

When Heinz, the manufacturer of the world’s favourite tomato ketchup, had an urgent need to double the steam capacity at their Telford plant Valveforce steamed into action providing detailed designs, load calculations, turnkey installation and project management. This resulted in the project being completed within tight timescales and a with a limited budget.

The task

Double the steam capacity to the production area to a very tight deadline during the busiest manufacturing period without affecting production.

The Valveforce solution

- Immediate site visit and project scope survey undertaken

- Detailed report produced within days specifying what needed to be done including:

- Heat-load calculations for pipe stress completed

- Thermal expansion calculations completed

- Pressure drop and flow load calculations completed

- CAD processing completed

- Layout diagrams completed

- Design plans for structural steels completed

- Designed the detailed plan for hanging pipes safely in the factory roof void

- Installed 300m of pipes in the cramped roof void

- All trades project managed by Valveforce

The output

Project completed and Heinz was able to carry out crucial product batch proving trials on time

An expert steam plant engineering partner

The contractor had worked with Valveforce before and they knew that they had the expertise, skill and the team to complete this large and complex project on time. Initially Valveforce was asked to survey the site and provide a project implementation report including all the relevant calculations.

“Valveforce was recommended to me as independent steam specialists with a track record of delivering turnkey projects. This was a big assignment requiring precision steam plant engineering and flexibility on the part of Valveforce to get the job done right in challenging working conditions to a very tight deadline. Valveforce had the dedicated team capable of executing the project professionally and pulled everyone together which meant the project was completed on time and to the budget. They are good people, very professional and they delivered a good job.” Andy Wood, Project Manager for Heinz, Protolan Limited

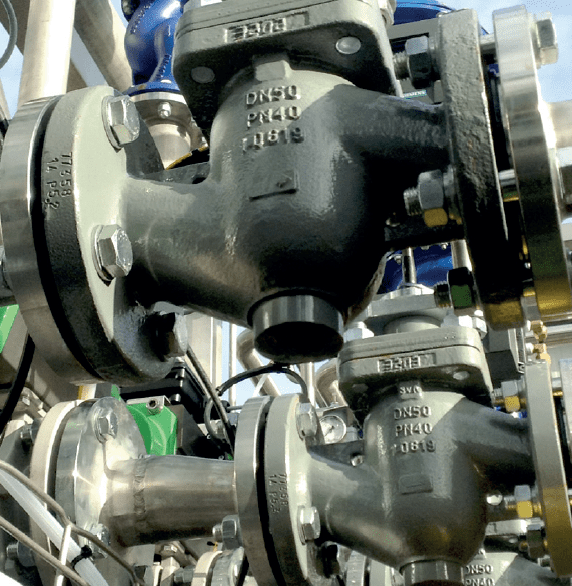

”This required Valveforce to extend the steam distribution system by sourcing, manufacturing and installing the new steam mains, all the valve fittings, steam equipment and 300 meters of 4” pipe including designing how the pipes would hang...”

Valveforce was subsequently employed to not only design the complete solution but perform the installation, working with Heinz’ s project manager to bring the whole project to completion and hand-over to Heinz.

Valveforce worked closely with Heinz’ appointed project manager Andy Wood who had been tasked with extending the steam distribution system for the Producing Sets and Control Sets in the kitchen. The kitchen is the production area where large batches of sauce production takes place. This required Valveforce to extend the steam distribution system by sourcing, manufacturing and installing the new steam mains, all the valve fittings, steam equipment and 300 meters of 4” pipe including designing how the pipes would hang in the roof void above the factory floor. All of this work was to connect the new steam mains from the boilers to the kitchen.

Challenges

Not only was the timescale testing, but there were other challenges:

- Installing major engineering work in a factory that was operating to full production capacity

- The work had to be completed outside of sauce production working hours so it had to be carried out through the night and weekends

- Working in the roof void to install 300 meters of 4” piping and hanging fixings which was cramped and difficult

The project plan was closely monitored with weekly project reviews. Owing to the timescale, sauce production schedule and working hours constraints Valveforce had to adapt and change the plan when required demonstrating a high level of flexibility with the installation, whilst ensuring that the steam got from the boilers to the production kitchen safely and at the correct temperatures and pressure.

Steam Engineering Specialists

Project management is essential in ensuring that all aspects of the design and build are synchronized with the customer as on-site production is very rarely stopped to allow for such installations. Valveforce work closely with the plant engineers to ensure deadlines are kept and budgets are maintained. With many years of experience in the food industry, Valveforce have a high level of skill in producing detailed design work, flow load calculation and installation. Valveforce believe good business is about relationships, building long term partnerships with customers to really understand their industry and effectively be an extension of their plant.

Valveforce Project Services

Audit and Design Work

- Independent Steam Systems Audits

- Heat and Energy Loss Insulation Audits

- Boiler BG01 and Water Treatment Audits

- Detailed consultancy and design specification

Service Agreements

- Boiler House Service Agreements

- Heat Exchanger Service Agreements

- Flow Metering Service Agreements

- Control Loop Service Agreements

- Plate Heat Exchanger Service Agreements

Survey and Testing Work

- Comprehensive Steam Trap Surveys

- High Temperature Protection Surveys

- Safety Valves In Situ and Off Site Testing

- Valve Repair and Testing

- Swap Out and Full Installation Site Works

Wish to make an enquiry? Need Support? ...or Have a Question? Speak with our Valve experts... Click Here

Download the latest Valveforce brochure here