Speak with our experts

Fill out our quick and easy contact form with your enquiry and we'll get back to you.

On-Site Servicing

By maintaining your pumping systems you will have peace of mind that they are in peak condition, ensuring they remain efficient and reliable. This keeps energy cost to a minimum and reduces the risks of unexpected and costly breakdowns. Should you have an unexpected breakdown, we are also here to help.

Our engineers carry out full servicing of your equipment on-site. A detailed report is provided, listing the condition of your equipment and our recommendations. We can then carry out any required repairs on-site or at our workshop with a quick turnaround.

Pump Maintenance Explained

Why is Maintenance of Plant Equipment Important?

An effective maintenance programme will make plant equipment more reliable. Fewer breakdowns mean less contact with equipment is required, as well as having the cost benefits of better productivity and efficiency, with additional hazards which can occur when equipment becomes unreliable and develop faults.

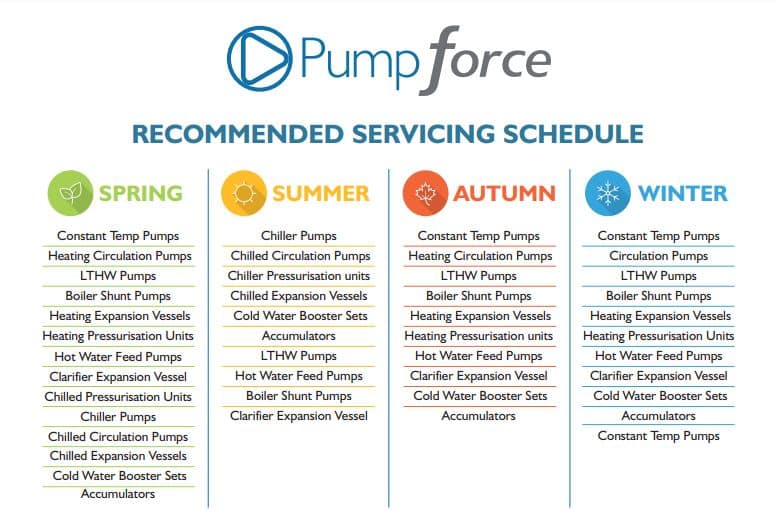

Maintenance allows these faults to be diagnosed early to manage any risks. However, maintenance needs to be correctly planned and carried out. Most organisations do not know how to correctly maintain their plant room equipment as a result their equipment perform sub-optimally, leading to downtime and excessive costs. Pumpforce believes in planned Preventive Maintenance with a schedule of maintenance procedures aimed at the prevention of breakdowns and failure of plant room equipment.

The primary goal of our preventive maintenance is to avoid the failure of equipment before it occurs. designed to preserve and enhance equipment reliability by replacing worn components before they fail. In addition, our engineers can record equipment deterioration, so they can schedule the replacement of parts.

Pumpforce Maintenance Plans

Pumpforce maintenance plans include:

- Inspect pumps for leakages, audible noise, dynamic stresses, and vibrations.

- Replacing motor bearings, mechanical seals, O rings, NRV’S, and overhaul or replace multistage chamber stacks.

- Commission all work carried out

- Keeping plant equipment running smoothly

- Preventing costly down times

- Keeping critical equipment in optimum condition

- Giving peace of mind knowing the crucial equipment has been maintained

- Preserving the life expectancy of plant equipment

- Reset service counter and alarms if applicable to the desired equipment

How Pumpforce can help

- Our Pump expert at Pumpforce can help you with all your Pump fault finding, replacement and repair needs – call us on 0121 461 6600.

Case Study - Maintenance

Extensive Site Survey for District Council

Pumpforce were contacted by a District Council to carry out a large site survey on pressure units, cold water booster sets, pumps, and expansion vessels.