Control Panel Design and Build

At Controlsforce we can design, build, program, test, deliver and install an extensive range of control system panels using the latest PLCs and HMI hardware and software.

Controlsforce are expert designer and manufacturer of bespoke control panels and systems, based in Solihull, West Midlands. We work across a wide range of industries, designing and building control panels and systems. Our highly skilled and experienced team use only the highest-quality components. All projects start with us getting to know the customers, ensuring we provide you with a custom-made and unique solution to meet your specific needs, no matter how straightforward or complex.

Speak with our experts

Fill out our quick and easy contact form with your enquiry and we'll get back to you.

Control Panel Manufacturers

Our dedicated team of control panel engineers, builders and designers have 30 years of experience in control panel design and building a variety of control panels.

These include:

- Pneumatic control panels;

- Hygienic design control panels;

- Remote control panels;

- Temperature control panels;

- Stainless steel control panels;

- Treadmill control panels;

- Conveyor control panels;

- Hydrostatic control panels;

- Bespoke on-off control panels;

- PLC control panels.

Control Panel Design Options

Control Panel Manufacturers

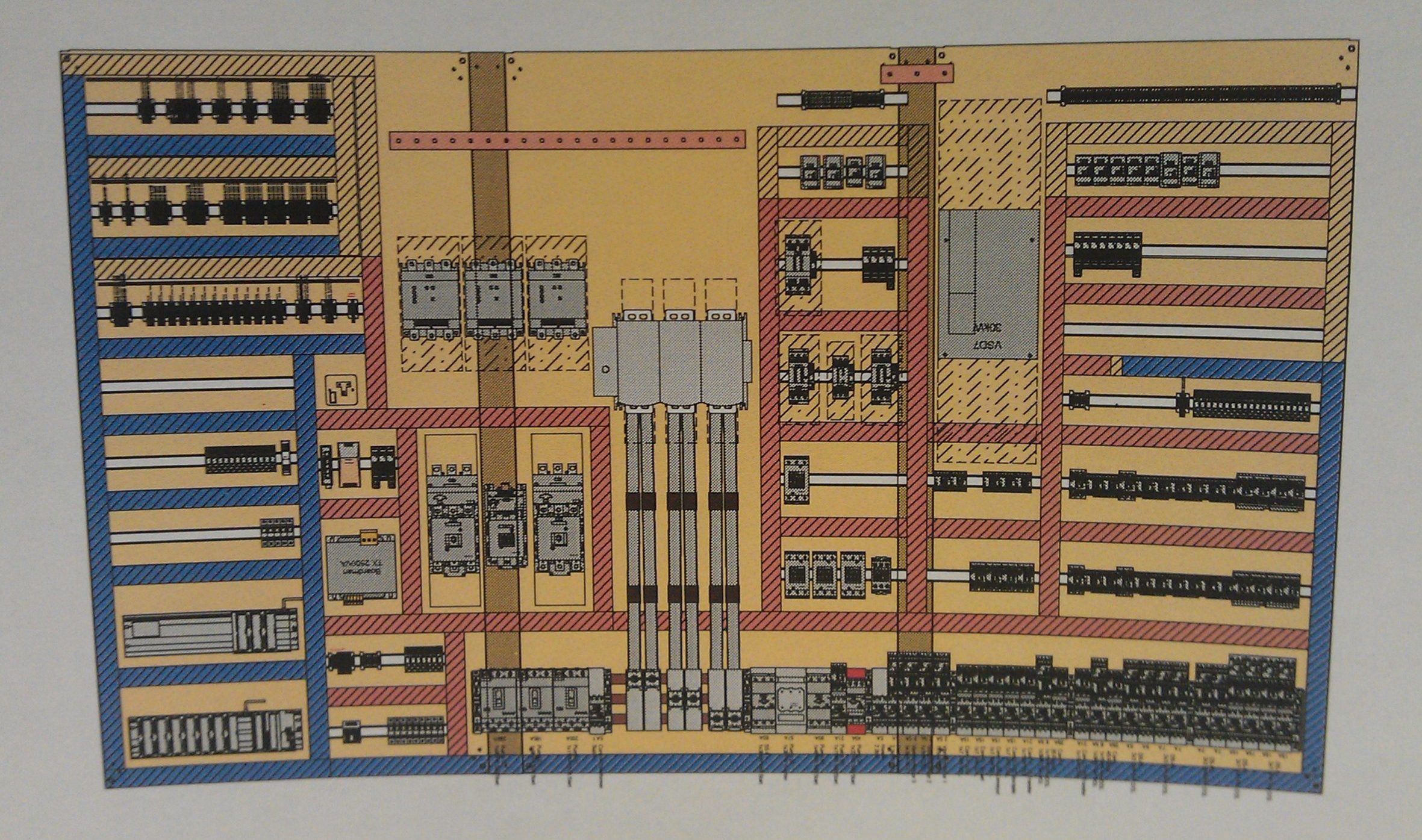

Our control panel design process begins by speaking with the customer to gain a full understanding of their needs and requirements. As well as, the applications of the panel or panels. This can be done by speaking to you over the phone, coming to your place of business or for yourself or one of your representatives to come visit us at our workshop. We can accommodate to whichever suits you best. Once you are happy that your needs have been clearly understood, we will begin the control panel design. This starts with designing the schematics for the panel, which is then given to the panel building team who will aim to complete each panel in a competent and efficient manner.

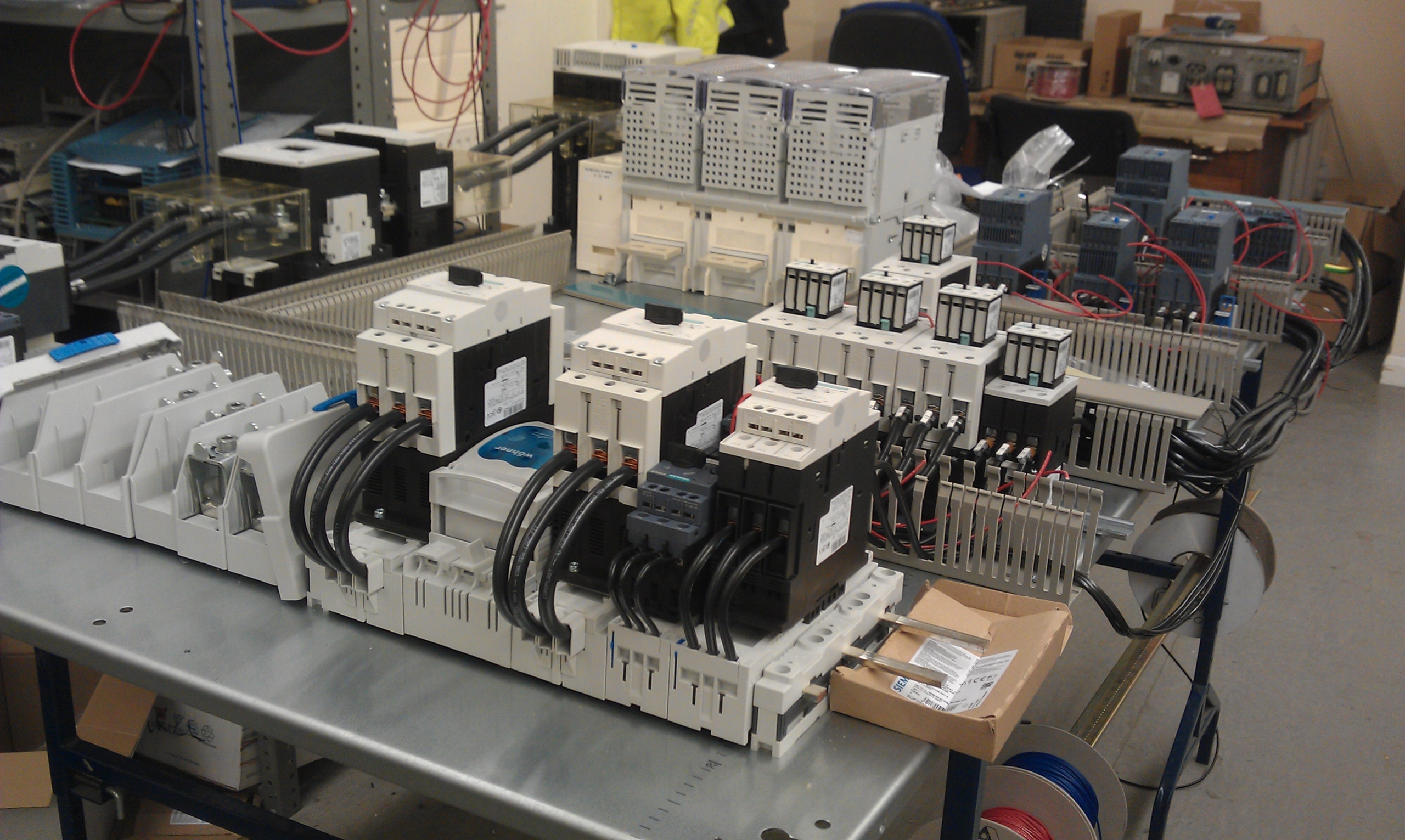

We take great pride, as a leading control panel supplier and manufacturer, in all the panels we build. The precision, cleanliness and neatness of each panel built is an integral factor in the minds of every panel builder at the company. All of our control panels are built with branded components from highly reputable companies, or customer specified parts, that conform to the regulations of the country where the custom control panels will be used.

Quality Assured Custom Control Panels

You can be assured that before any custom control panels leave us, every screw and cable will be checked for tightness and the panel will be cleaned inside and out. In addition, all systems are electrically tested for safety and correct operation, documented and photographed for future references before being packed for delivery.

In addition to building industrial custom control panel design and other control units in our workshop, we also offer on-site maintenance and repair services. With this service, we will come to your place of business to deal with your enquiry.

This could include:

- PLC/HMI programming

- Replacing and upgrading faulty drives, circuit breakers and other components in an industrial control panel

- Rewiring existing control panels

- Making alterations and/or additions to existing panels to better suits your needs

PLC and HMI DCS / SCADA Systems

ABB PLCs; Allen Bradley PLCs; Beijers HMIs; GE PLCs; Mitsubishi HMIs; Mitsubishi PLCs and Alpha; Omron PLCs; Proface HMIs; Rockwell HMI – RSVIEW; Schneider HMIs; Schneider Modicon PLCs and Zelio; Siemens HMI - WINCC; Siemens S5/S7 PLCs and Logo; Unitronics PLCs; Weintek HMIs and many more

At Controlsforce we can also:

- Incorporate PC based control using SOFTLOGIX, TWINCAT, HMI/SCADA, VB .NET and more

- Provide remote access over the internet via cabled, wireless and mobile networks

- Supply low cost combined PLCs and HMIs

We are very proud of our control systems and are happy to provide support and updates if and when required.

HMI Screens

From designing your system to the most specific of requirements, Controlsforce can program your machine/plant to operate autonomously or manually. We can give you complete control of your process and allow you to monitor operation and log data. We can incorporate HMI screens to allow you to change processes or adjust individual sections of the operation in order to make your plant/machine operate efficiently and cost effectively.

Our team of experts at Controlsforce can design HMI screens to incorporate your company branding and the screens can be password protected to prevent accidental or unauthorised changes to your process. We can support multiple user languages or design an info-graphic and icon based interface for general operator interaction and we can keep a log of all user interactions if required.

Variable Frequency AC Inverter Drives

Automotion Control System

Parameters can be set for and monitor a number of things such as motor voltage, current, speed, power factor, torque, temperature etc and can set for local or remote control operation such as start, stop forward, reverse. Incorporating AC inverter drives in the design and build of electrical control panels can be the best way to control ac induction motors on large industrial plants with possible large energy and cost savings.

At Controlsforce we can design, build, test, deliver and install an automation motion control system controlling and monitoring machine moving parts in a safe controlled manor. It could incorporate open or closed loop motion control commands through an energy amplifier to operate actuators and the like, it could be used for fan control, stepper motor control, hydraulic pumps, pneumatic cylinders etc. using measuring devices it could monitor velocity and point to point positions of machines using measuring devices such as servo’s, resolvers and incremental encoders for more accurate positioning as in the operation of CNC and robotic machines and plant. It could include Ethernet/IP, Profinet IRT, Ethernet Powerlink and EtherCAT

Electric 3 Phase Induction Motor

Using an AC inverter drive is the most efficient way to control an electric 3 phase AC induction motor. It offers speed and torque control of the electric AC induction motor to match the process it is to be used for, thus not wasting energy, improving productivity and reducing maintenance costs which is good for the business and environment.

Simply the AC Inverter drive works by tacking ac electrical mains either single phase or three phase and rectifying it into direct current (dc). The direct current is usually passed through smoothing capacitors and sometimes a dc choke before connecting to power transistors, which turn it into 3 phases for the motor. The inverter drives usually have many programmable parameters which can be accessed and changed to suit the requirements of the operational needs of the ac induction motor.

Motor Control Centres

If you require we can design, build, test, deliver and install a motor control centre for you, from single bay to multi bay motor control centres keeping the control of your plant in one location. They could be multi cubicle common power bus sections with each cubicle containing a lock off power disconnect isolator, motor starter, fuses or MCB’s.

At Controlsforce, we are confident that by using top quality components and equipment, you can be sure that the motor control centre will give you many years of service.